Businesses need operational efficiency to function at their best and avoid wasted time or unnecessary costs. Operational efficiency enables businesses to save time, eliminate waste, and improve systems.

But, how do you discover what’s taking up bandwidth or where projects are falling through the cracks?

Our article will explain operational efficiency measures and teach you how to use them to streamline your business processes.

Boost your team’s efficiency with Hubstaff's productivity tools

Try it free for 14 daysWhat is operational efficiency?

Operational efficiency is improving processes and systems to achieve optimal output and goals without compromising the quality of the organization’s offerings.

With high operational efficiency, businesses can maximize profitability while cutting costs. Companies may want to focus on increasing productivity over efficiency, but it’s essential to know the differences between productivity and efficiency to determine the correct KPIs and targets.

Suppose you implement a new process that reduces resource usage but increases speed; congratulations! This is what operational efficiency looks like.

One more concrete example of operational efficiency is investing in high-quality equipment. These investments would maintain consistent productivity while eliminating the need for frequent maintenance. Although the initial costs of this equipment may be higher, the long-term costs would be lower, and overall efficiency would allow for increased profits.

What are some factors that affect operational efficiency?

What’s a part of operational efficiency? Several factors influence operational efficiency within an organization. These factors may include:

Technology

One of the main factors that can hurt operational efficiency is the type of technology a business uses. Along with the equipment itself, consider what software and hardware you use.

For instance, if your HR department manually tracks employee schedules and invoices in a spreadsheet, they might save money on the monthly cost of a billing solution. However, in the long run, having all-in-one workforce management software will make the organization more efficient and prevent human errors.

Equipment is more than just laptops and phones. Efficiency affects heavy machinery and assembly lines, too. The risk of breakdowns due to low-quality or poorly maintained equipment could lead to costly downtime. Some equipment may even present safety risks that could cause harm to employees or other equipment, further reducing efficiency.

Research and development are also necessary, as they help identify and develop new and more efficient technologies you can integrate. Continuous improvement through process management will ultimately lead to increased overall efficiency.

Human elements in operations and management

Several human components may also influence operational efficiency. Your goal should be to minimize the risk of human error by hiring the right people. These and other initiatives can facilitate a productive and efficient work environment.

Staff must have the necessary skills and competencies to help optimize the efficiency of business operations. Highly efficient employees will also need fewer resources, so you may not need as much additional staff or equipment.

Often, however, employees are only as good as their tools and management. Give them the software, equipment, and leadership they need to get the job done.

Remember that fatigue is a hindrance that can negatively affect decision-making abilities and efficiency. It may lead to less productivity and increase the risk of human error.

Further, though it might not correlate directly to sales, it’s essential for overall efficiency that you spend time doing things that boost employee morale. Taking retreats, offering employees the day off for their birthday, or including benefits like tuition reimbursement and wellness stipends are all great options.

Organizational aspects of operational efficiency

The company must also take specific steps to facilitate operational efficiency throughout the organization. For example, if a company doesn’t have sufficient supervision in place, this could lead to:

- Lowered input and output

- Poor task and project management

- The potential for errors and accidents

- Inefficient systems and structures

- A closed off-culture that’s not open to change or feedback

Additionally, organizations need training and development programs to promote operational excellence.

Without these programs, staff may not operate equipment and systems properly, and efficiency will suffer. Insufficient training could also lead to human error, while a lack of development programs could limit employees’ ability to grow.

Together, all of these factors contribute to operational effectiveness and efficiency. So it is crucial to address each of them if you want to streamline processes and optimize resource utilization.

How to measure operational efficiency

To determine whether your efforts are working when it comes to increasing operational efficiency, you need to be able to measure the results. This process involves identifying key performance indicators (KPIs).

The following are some specific steps to take to measure operational efficiency.

Step 1: Set a baseline

The first step is to record your organization’s current operational efficiency and employee performance data. Then, if possible, compare this baseline level to your competition.

During this process, you can determine which elements of your operations to optimize based on your goals. When setting your goals, you can select specific KPIs to help measure your success and help with benchmarking.

Some benchmarks might include straightforward metrics like products shipped or customers onboarded. But you’ll also want to measure things like employee satisfaction.

This process will give you a roadmap to help guide you toward increased automation and optimized workflows.

Step 2: Assign responsibility to specific team members

As you determine the goals and tasks you need to perform to meet those goals, figure out which team members should be responsible for each job.

Every team member will have a different perspective on what is operational efficiency. For example, you may have content marketers create content while a project management team handles process mapping.

Also, consider how your team members will complete their respective tasks. How much time will each task take, and how many tasks are repeatable? How exactly will your staff complete these tasks?

Answering questions like these can help you figure out how to spend less time on unimportant tasks. In addition, it will increase your team’s focus and help further optimize efficiency.

If you’ve hired a capable team, remember that they all have expertise and experience — use that to your advantage. Get their feedback, insights, and wisdom before you proceed.

Step 3: Look for bottlenecks that prevent progress

Once you’ve decided on the tasks your teams need to complete (and who will handle them), you must watch for bottlenecks that might hold you back. These bottlenecks could include any steps or activities on which your team might be wasting time and resources as they complete various tasks.

With time tracking software, you can identify different bottlenecks in your operations by tracking employee workloads and gaining insight into each team’s performance. For instance, you might find that tasks don’t need to go through as many approvals as they currently do. You may also determine that employees spend more time than they need to on a particular task as they strive to meet deadlines.

Bottlenecks aren’t always obvious. You’ll have to pay close attention to each step of your process. Don’t be afraid to get into the weeds and deep into details.

Step 4: Work toward eliminating those bottlenecks

After identifying all the bottlenecks in your operations, work to remove them. For example, you may find that one team spends too much time on a particular task that another team could handle.

By assigning this task to the second team, you can free up more time for the former to complete even more work. Doing so will help increase work efficiency while reducing operating expenses. It also keeps quality levels the same as you give each team the appropriate amount of work.

Step 5: Measure performance

The last step is to measure your organization’s performance. Using a spreadsheet or project cost management software, take a look at your KPIs and compare them to your previous numbers. Based on these numbers and your goals, you can determine whether you’re succeeding with your efforts.

You should also ensure that your optimization efforts aren’t sacrificing the quality of your offerings. Otherwise, your attempts to boost operational efficiency could lead to a decrease in customer satisfaction.

Don’t forget to celebrate your improvements and wins with your team. If you’ve seen steady growth, you can owe that to the hard work and effort of employees. They’ve been making processes faster, while also engaging in operational experimentation.

What is operational efficiency worth to your organization?

With the help of the correct methodology and processes, your business can benefit from increased operational efficiency.

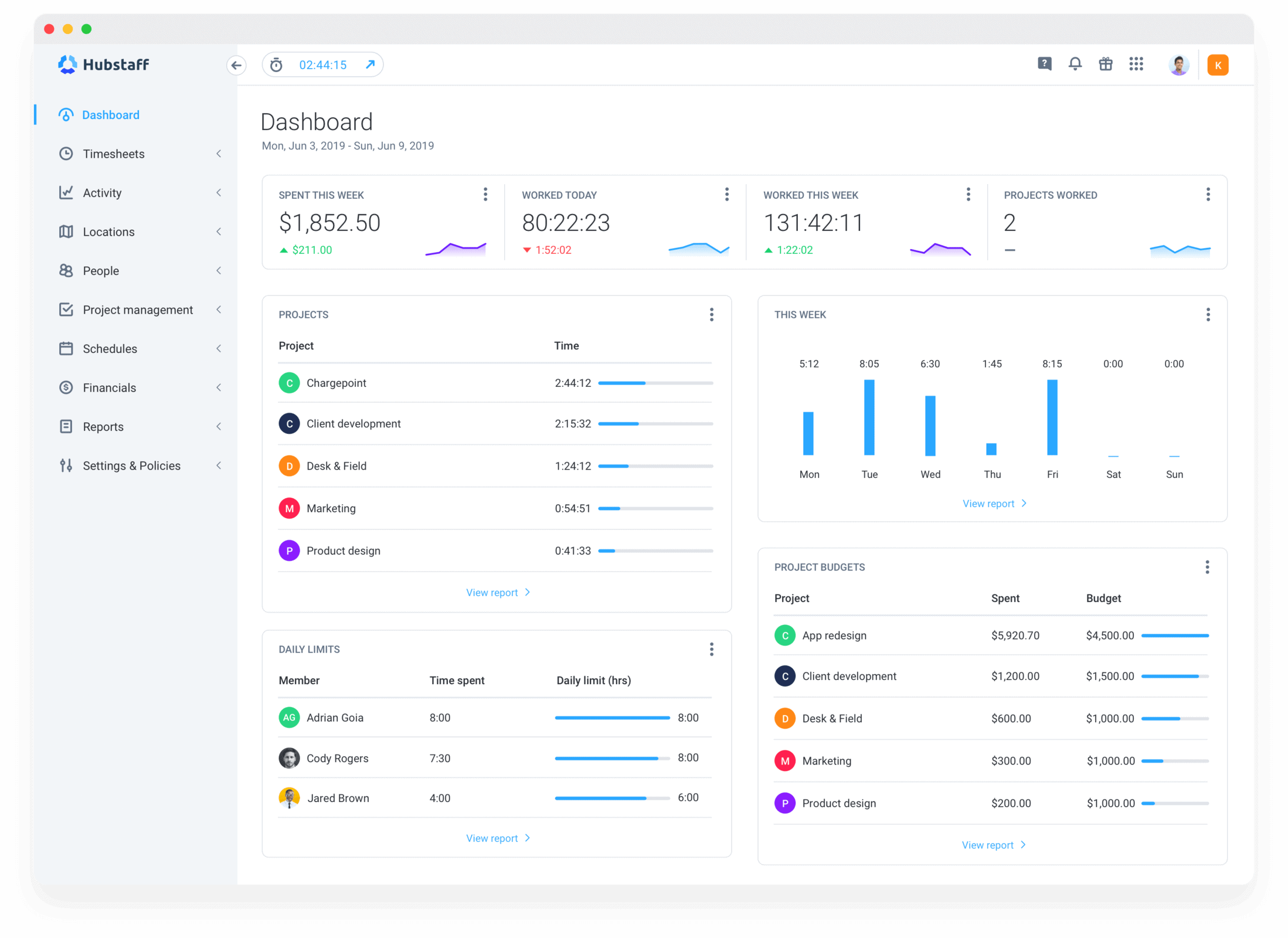

Innovative dashboards and business software will give you the in-depth insights and accurate data you need to measure your success.

Use a tool like Hubstaff Tasks to track your tasks and your progress toward operational efficiency. Over time, you’ll see improved results as you work toward achieving and even exceeding your business goals.

Discover a simple way to manage your projects with Hubstaff Tasks, or manage your employees’ schedules, timesheets, and billing with Hubstaff. Start your 14-day trial to increase your workforce and operational efficiency.

Subscribe to the Hubstaff blog for more posts like this

Most popular

How to Calculate a Raise: Practical Guide for Employers

By 2030, the US alone will lose $430 billion annually due to low talent retention — and a lot of this turnover stems from low pa...

How to Survive and Thrive in an 80-Hour Work Week

It’s hard to believe that only a century ago, the 80-hour work week was the norm in the United States. Then, in 1926, the Ford M...

Mastering Workforce Scheduling: Techniques and Tools for Success

Imagine a workday where scheduling your workforce effectively ensures that every shift is perfectly aligned with your business nee...

Top Time Trackers for Virtual Assistants: Enhance Efficiency and Accountability

Virtual assistants (VAs) have a lot of responsibilities — and so do the people who hire them. With so much to keep track of, a t...